Medical breakthroughs and new materials are often used in orthopedic surgery to help patients do better. Using HA (Hydroxyapatite) covered Break Thru Poly Axial Screws is one example of an improvement. These HA Coated Poly Axial Screws are better than regular screws in several ways, which makes them a valuable addition to spinal implant surgery.

Understanding HA Coating

A porous material called hydroxyapatite (HA) layer is often used in orthopedic surgery to help implants fit better with the bone tissue around them. The minerals that make up this layer, calcium phosphate, are very similar to those that make up human bone. By making osseointegration better, HA covering can make orthopedic devices like screws, plates, and replacements much more stable and last longer.

How it works

Osteoblasts, the bone cells, stick to implants with an HA layer because the HA particles make the surface rough. Because of osteoconduction, new bone tissue can grow on the implant, making it part of the surrounding bone.

Break Thru Poly Axial Screws

Orthopedic devices called Break Thru Poly Axial Screws are made to be used in spine operations.

The polyaxial form of these screws gives you more options for where to put them and how to line them up compared to standard monoaxial screws. The “break-thru” design means that the screw head can separate from the shaft, which makes it easier to remove if needed.

Having hydroxyapatite (HA) on these screws makes them better in some ways. HA is a useful substance that helps bone grow and osseointegration, the process by which the implant joins with the bone around it. This can help the bone fuse faster and make the implant more stable.

The low profile and practical design of HA Coated Poly Axial Screws make them suitable for a number of spinal conditions, such as degenerative disc disease, deformities like scoliosis, kyphosis, lordosis, and injuries to the spine. Because they are polyaxial, they can better adapt to the natural curve of the spine, which lowers the chance of problems and improves patient results.

Advantages of HA Coated Break Thru Poly Axial Screws

The benefits of using HA coated Break Thru Poly Axial Screws in orthopedic surgery are substantial and include several factors that lead to better patient results. They have many benefits that help patients improve, and the implants last longer. Some significant benefits are listed below:

Enhanced Osseointegration

It makes osseointegration easier because the HA layer helps bone grow faster and stronger on the screw surface. This makes it easier for the implant to stay in the bone, lowering the risk of it getting loose or moving.

Faster Fusion

HA-coated screws can speed up the fusion process in spine surgeries by helping the bone grow. This is especially helpful for surgeries like spine fusion, where strong bone fusion is essential for long-term success.

Better Protection Against Infections

HA’s antibacterial features can help lower the risk of infections after surgery. The HA layer roughs the surface, which can also stop germs from sticking to it. This reduces the risk of infection around the implant site even more.

Increased Biocompatibility

HA is biocompatible, meaning the body can handle it well and doesn’t have a bad defensive response to it. To make HA coated screws ideal for a wide range of patients, it lowers the chance of allergic reactions or implant failure.

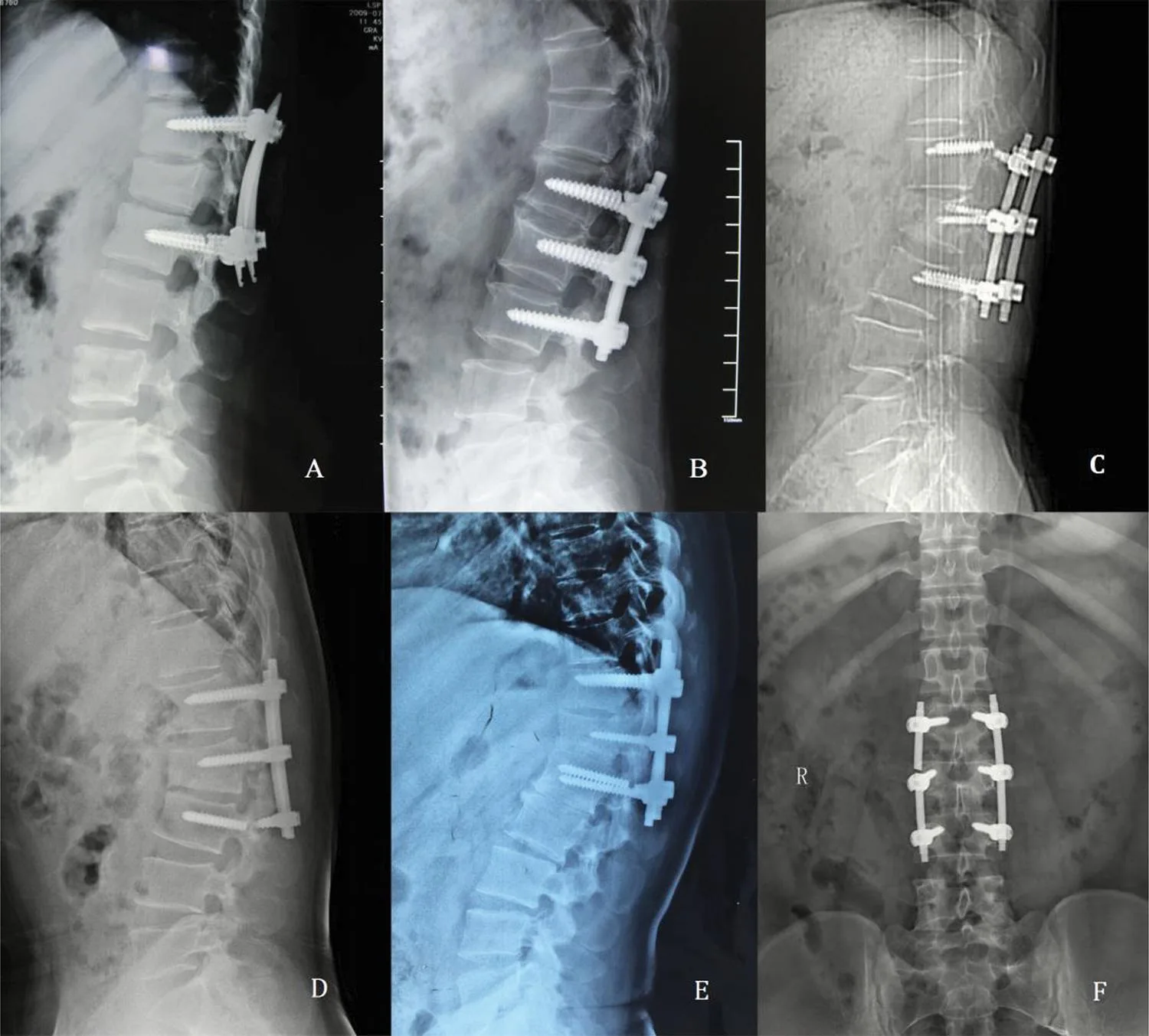

Better Radiopacity

Imaging scans like X-rays and CT scans can see through the HA covering better because it is less radioactive. Better radiopacity lets doctors see more clearly where the screws are and how well they’re integrating into the bone. This leads to better planning for surgery and better review afterward.

Polyaxial Design

HA Coated Poly Axial Screws have a polyaxial form that makes them more flexible and adaptable during insertion. This helps doctors put screws in the right place, even in hard-to-reach body parts and lowers the chance of screws being out of place or misaligned.

Applications in Orthopedic Surgery

When it comes to orthopedic surgery, HA coated Break Thru Poly Axial Screws are very useful, especially in procedures that deal with the spine and other places where muscular stabilization and osseointegration are very important. Here are some of the most important uses:

- Spinal Fusion

These screws are often used to support the spine and help the bones fuse during spinal fusion surgery. The HA layer improves osseointegration, which makes fusion happen faster and stronger. This is important for healing diseases like degenerative disc disease, spondylolisthesis, and spine injuries.

- Degenerative Disc Disease (DDD)

HA-coated screws can be used to treat degenerative disc disease (DDD), in which the discs between the vertebrae break down and cause pain and weakness. The screws help keep the damaged vertebrae stable and encourage fusion, which eases the pain and makes the spine stable again.

HA coated screws can be used to support the damaged vertebrae and speed up the healing process after spinal fractures or other types of traumatic injuries to the spine. HA coatings can help implants stay firm during mending by making it easier for bone to fuse with them.

Not as popular as spine surgery, joint arthroplasty uses HA-coated screws in treatments like hip or knee replacements. The screws can help keep the artificial parts stable and encourage osseointegration, which will make the joint replacement last longer.

Surgical Techniques and Considerations

Surgical methods and things to think about are very important for using HA-treated Break Thru Poly Axial Screws successfully in orthopedic surgery.

1. Planning Before the Surgery

Planning before the surgery is very important to find the best screw size, length, and path for each patient’s body. This might include using X-rays, CT scans, or MRI scans to check the quality of the bone and plan where to put the screws.

2. Soft Tissue Management

With the soft tissues around the operating site carefully managed, it is possible to get to the spine during surgery. This might include methods like tissue withdrawal or incision to protect nearby organs as much as possible.

3. Implant Placement

Surgeons have to make sure that the screws are in the right places so that the bones can fuse together and stay fixed. These screws’ polyaxial form gives you more options for where to put them, but be careful not to damage structures nearby.

4. Screw Insertion

Surgeons should use the right tools and methods to make sure the screws are in the right place and at the right depth when they install them. If the screws are too tight, they can hurt the bone, and if they are too loose, they might not hold the bone in place properly.

5. Post-operative Care

Patients should be closely watched for any signs of problems after surgery, like an illness or an implant getting loose. Patients may need physical therapy and training to get their strength and movement back.

Challenges and Future Developments of HA Coated Break Thru Poly Axial Screws

HA coated Break Thru Poly Axial Screws have many benefits, but they also have some problems in surgery. Surgeons and researchers need to think about these challenges and how the field will change in the future.

Challenges

- Cost implications and accessibility

- Need for specialized instruments and surgical training

- Long-term durability and performance

- Risk of infection despite HA coating’s antimicrobial properties

- Biomechanical effects on spine load distribution

- Potential for patient-specific implants using 3D printing

- Regulatory approval processes and streamlining for new technologies

Future Developments

- Enhanced durability and longevity of HA coatings

- Development of cost-effective HA coating technologies

- Advancements in specialized instruments and surgical techniques

- Research on optimizing load distribution and stress patterns

- Exploration of alternative coating materials with improved infection resistance

- Implementation of patient-specific implants using 3D printing

- Streamlining regulatory approval processes for faster adoption

Wrapping It Up

Break Thru Poly Axial Screws with HA Coating are a big step forward in surgery. Due to their versatility, these screws are helpful for many spine surgeries and other medical treatments, ultimately leading to better patient results. Even though there are some challenges, research and development are still working on more things to make sure they continue to be very important in making hip surgery better.