In a world of seemingly small components, transverse connector innovations have significance in fields as diverse as orthopedics, engineering, and more. When it comes to structural integrity, technological progress, and the future of many different industries, these connectors are the invisible warriors. This article looks into the importance of transverse connectors and how recent developments are changing the face of orthopedics, engineering, and other fields.

What Is Transverse Connector

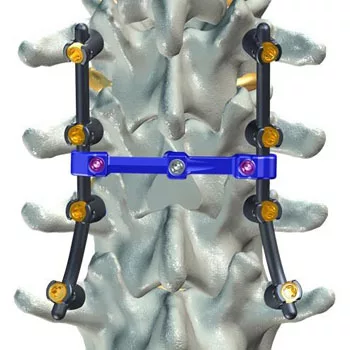

In order to enable effective fusion and restore spinal function after surgery for a disease requiring fusion, spinal stability, and support are frequently necessary. In these cases, a transverse connector is important.

It provides structural support for the spine during fusion, which promotes healing and reintegration of the fused spinal segments.

It is commonly used with spinal instrumentation like pedicle screws and rods to improve the fusion process and limit motion between vertebrae.

Transverse connectors play an important role in providing structural integrity and mechanical support during orthopedic surgery.

- Applications in Spinal Surgery

- Supporting Joint Replacements

- Promoting Fusion in Orthopedics

The Basics of Transverse Connectors

Orthopedic operations rely heavily on transverse connectors. These connectors are essential for maintaining spinal and joint stability during invasive procedures. One must be familiar with their nature and role in orthopedics before being able to fully understand their relevance.

The anatomical, structural, and mechanical aspects of transverse connectors make them valuable for orthopedic procedures.

Methods for Transverse Connector

The objective of spinal fusion surgery is to promote the fusion of adjacent vertebrae, leading to the formation of a continuous bone structure that immobilizes the affected area of the spine.

The fusion process relies on the generation of fresh osseous tissue between the vertebrae, ultimately resulting in their merging.

Minimizing movement at the surgical site is important to ensure adequate bone development and integration.

Stability is of utmost importance in spinal fusion surgeries. It is important to maintain immobility at the surgical site when fusing two or more vertebrae to facilitate good bone development and fusion.

Excessive motion can disrupt the fusion process, leading to complications such as pseudarthrosis or failure of the instrumentation.

Transverse connectors resolve this problem by enhancing stability, reducing stress at the fusion point, and facilitating the formation of a compact fusion mass.

The Role of Transverse Connectors in Engineering

To guarantee the reliability, security, and lifespan of structures and systems, engineers rely heavily on transverse connectors. Their influence extends to a wide range of engineering fields, including civil, structural, mechanical, and aerospace design.

In order to improve the efficiency and durability of transverse connections, engineers are always looking for new methods to use them.

- Structural Stability

- Structural Health Monitoring

- Connection of Structural Members

- Innovations and Advanced Materials

- Alignment and Positioning

- Materials and Corrosion Resistance

- Disassembly and Maintenance

- Load Transfer

- Environmental Impact

- Vibration Damping

- Failure Analysis

Factors to Consider in Transverse Connector Selection

Choosing the appropriate transverse Connector for orthopedic operations requires careful consideration of these parameters. Indeed, below, you will find a list of, and brief descriptions of, the most important criteria to keep in mind while choosing a transverse connector in orthopedics.

- Orthopedic Condition Severity and other patient-specific characteristics need to be considered.

- Orthopedic surgeries have varying transverse connector needs.

- Guarantee the Connector is suitable for usage with the other surgical implants.

- The connecting material must be appropriate for implantation and biocompatible.

- Consider the patient’s size and shape while selecting a connection to use during surgery.

- Biomechanical properties should be taken into account while choosing a connector.

- Keep up with developments in connector technology and use them in your own work.

- Success in surgery relies heavily on the surgeon’s knowledge of a specific type of connection.

- Evaluate the Connector’s capability of withstanding repeated everyday stresses throughout time.

- Be sure the Connector meets all safety and regulatory requirements for medical equipment.

- Regarding the patient’s specific needs and wants, you should take them into account.

- Consider the hazards that may arise from using the Connector and make an assessment.

- Consider what kind of follow-up care and upkeep will be required after surgery.

Beyond Engineering: Applications in Other Fields

Transverse connectors have applications beyond engineering, spanning various fields which are listed below.

- Medicine

- Consumer Goods

- Telecommunications

- Telemedicine

- Environmental Sciences

- Industrial Equipment:

- Automotive

- Aerospace

Transverse Connector Innovations And Advancements

The development of transverse connectors parallels the development of technology and materials. Orthopedic operations have become more effective and patient-centered as a result of transverse connector innovations in design, materials, and biomechanical qualities.

Improved health outcomes, faster recoveries, and minimally invasive procedures are all possible due to these advancements.

Challenges and Concerns Of Transverse Connector Innovations

Surgeons and support workers using Transverse Connector should familiarize themselves with the device’s safety precautions and warnings in these instructions and elsewhere in the product description, surgical procedures, and/or literature.

The connectors are planned, developed, and manufactured with the most excellent care and are made from medical-grade materials. If used correctly, this high-quality Connector guarantees optimal performance. For this reason, please read and follow the usage instructions and safety advice below.

Tissue damage, premature wear, instrument destruction, and operator, patient, and bystander injury are all possible outcomes of Transverse Connector misuse.

The surgeon in charge of an operation must be involved in the care of the patient he or she treats. The surgeon needs to be well-versed in all facets of the process, from the tools to their limitations.

It is the obligation of the surgeon and the surgical team to choose and use surgical equipment with care. The use of implants should await the completion of adequate surgical training.

Factors that could hinder the operation

- Sensitivity to artificial implants.

- Local bone tumors.

- Fragile bone disease; osteoporosis or osteomalacia.

- Disturbances in metabolism and other systemic diseases.

- Drug and alcohol misuse.

- Extreme shocks and loading on the implant.

- Individuals who are mentally incapable of following a doctor’s orders.

- Wellness issues.

Potential Adverse Effects

The most prevalent unwanted outcomes of implantation are as follows.

- Connector loosening is caused by tissue reactivity to the implant or repeated loading of the fixation point.

- Acute and chronic infections.

- Bone weakness or stress fractures might lead to further fractures.

- Pressure or bleeding can cause either short-term or long-term neurological injury.

- Bleeding and condition at the incision site; slow healing.

- Venal thrombosis, pulmonary embolism, and cardiac arrest.

- Osteogenesis at an abnormal place.

- The Transverse Connector causes pain.

- Bending, loosening, or breaking of the implant due to mechanical failure.

- Implant migration leads to tissue damage.

Transverse Connectors: Key Components of the Future

The future of transverse connections is bright, both in engineering and beyond. As time goes on, these seemingly insignificant parts will prove to be crucial in driving innovation, sustainability, and technical progress across many other fields.

As we approach an exciting new phase, it is clearly obvious that transversal connectors will continue to play crucial roles in shaping both the foundations of progress and the world as we know it.

Wrapping It Up

Although transverse connectors are often disregarded, they serve an essential purpose in orthopedics and engineering and have far-reaching implications in other disciplines. Future engineering will rely significantly on transverse connectors, which will open the way for intelligent and sustainable solutions across a range of industries, from medical to aerospace.