In recent years, orthopedic surgery has seen significant advances in implant technology, particularly with the introduction of 3D printing. Polymethyl methacrylate (PMMA) has emerged as a versatile and promising material for the additive manufacture of orthopedic implants.

In recent years, orthopedic surgery has seen significant advances in implant technology, particularly with the introduction of 3D printing. Polymethyl methacrylate (PMMA) has emerged as a versatile and promising material for the additive manufacture of orthopedic implants.

In this article, we will examine the aesthetics and strengths of PMMA 3D-printed implants, highlighting their unique features, uses, and patient benefits.

What are PMMA 3D Implants?

Polymethyl methacrylate (PMMA) is a synthetic polymer noted for its transparency, strength, and biocompatibility. It is widely used in medical equipment, dental prostheses, and bone cement. PMMA has excellent mechanical qualities and is easy to process, making it an ideal material for 3D printing applications in orthopedic surgery.

Advantages of PMMA 3D Printed Implants

Biocompatibility

PMMA is usually recognized as a biocompatible material, which means the human body readily accepts it and causes no adverse reactions or immunological responses. This makes PMMA a great candidate for orthopedic implants since it reduces the risk of rejection and problems after surgery.

Aesthetic Appeal

One of PMMA’s primary advantages is its transparency and ability to resemble the appearance of genuine bone tissue. This aesthetic aspect is especially essential in cosmetic and reconstructive surgeries when implant visibility is an issue. PMMA 3D-printed implants merge well with the surrounding tissues, improving the overall appearance of the surgical result.

Customization

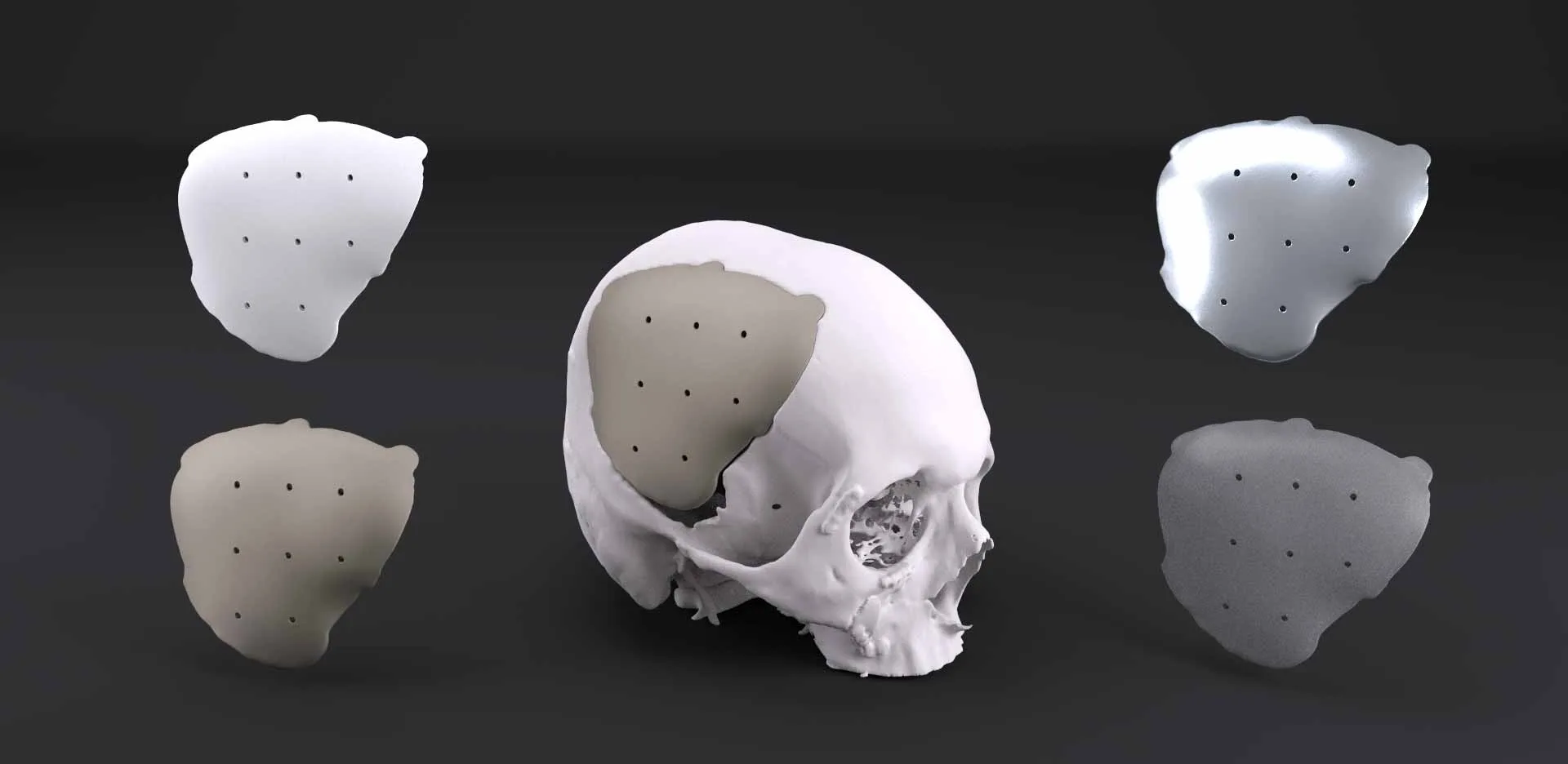

3D printing technology enables the exact customization of implants based on each patient’s unique anatomy. PMMA implants can be customized to match individual bone shapes and dimensions, ensuring the best fit and function. This customization improves surgical precision, minimizes the need for intraoperative corrections, and improves patient outcomes.

Mechanical strength

Despite its lightweight and transparent nature, PMMA has remarkable mechanical strength and stability. PMMA 3D printed implants offer firm support and fixation, tolerate physiological pressures, and promote long-term durability. This strength is beneficial in weight-bearing applications like joint replacement and spinal fusion.

Applications for PMMA 3D Printed Implants

Total joint replacements

PMMA 3D printed implants are increasingly used in total joint replacement surgeries, such as hip, knee, and shoulder replacements. These implants provide superior biocompatibility, precise customization, and long-lasting support, resulting in enhanced joint performance and patient satisfaction.

Craniofacial reconstruction

PMMA implants are widely utilized in craniofacial reconstruction surgeries, where they restore facial symmetry and beauty after trauma or congenital defects. PMMA’s transparency and flexibility make it a perfect material for designing patient-specific cranial and facial implants that blend in with the surrounding tissues.

Spine Surgery

PMMA 3D printed implants are used in spine surgery to enhance vertebral bodies, fuse them together, and treat spinal abnormalities. These implants offer solid fixation, optimum alignment, and improved osseointegration, resulting in good outcomes for patients suffering from degenerative spine disorders or spinal traumas.

Orthopedic Trauma

PMMA implants are also used to treat orthopedic trauma, including fractures and bone abnormalities. Whether employed as temporary fixation devices or permanent implants, PMMA 3D-printed implants provide dependable support, promote rapid healing, and lower the risk of complications in severe injury cases.

Benefits to Patients

The use of PMMA 3D printed implants in orthopedic surgery provides several significant benefits to patients, including:

Enhanced Aesthetics

PMMA implants blend in smoothly with natural tissues, enhancing the cosmetic look of surgical outcomes while increasing patient confidence and happiness.

Improved functionality

Patients with musculoskeletal diseases or injuries benefit from customized PMMA implants that give precise fit and alignment, restoring joint function, stability, and mobility.

Reduced complications

The biocompatibility and mechanical strength of PMMA implants reduce the possibility of implant-related problems like infection, loosening, and failure, resulting in better long-term results.

Accelerated recovery

PMMA implants enable faster healing and osseointegration, allowing patients to return to normal activities and improve their quality of life.

Future Directions and Innovation

Advanced Materials Development

Future advances in PMMA 3D printed implants may include the creation of innovative materials with improved mechanical qualities, biocompatibility, and degradation resistance.

Researchers are investigating the use of composite materials, bioactive chemicals, and nanotechnology to enhance the performance and functioning of PMMA implants.

For example, integrating bioactive chemicals such as growth factors or antimicrobial agents into PMMA formulations can improve tissue regeneration and lower infection risk, resulting in better clinical outcomes for patients.

Multi-material Printing Techniques

Another area of advancement is the incorporation of multi-material printing techniques into the manufacturing process for PMMA implants. By combining multiple materials with diverse qualities into the implant design, surgeons can personalize implants to specific patient needs and anatomical requirements.

Multi-material printing allows for the production of complicated implant geometries, tailored surface textures, and graded structures that improve mechanical performance and tissue integration. This method has the potential to increase the variety of uses for PMMA implants, such as sophisticated reconstructive operations and tissue engineering.

Biomechanical optimization

Future study will focus on improving the biomechanical performance of PMMA 3D printed implants using advanced computational modeling and simulation approaches.

Researchers can improve implant designs by studying their stress distribution, load-bearing capacity, and fatigue behavior under various loading circumstances.

Biomechanically optimized implants have the potential to increase implant fixation, reduce mechanical failure risks, and improve patient outcomes in orthopedic surgery.

Personalized Medicine Approaches

With the growing availability of patient-specific imaging data and digital modeling technology, the future of PMMA 3D printed implants is in personalized medicine techniques.

Surgeons can employ advanced imaging techniques like CT scans and MRI scans to build very accurate digital models of the patient’s anatomy, allowing implants to be precisely customized to specific bone curves and dimensions.

Personalized implants provide higher fit, alignment, and biomechanical performance, resulting in better surgical outcomes and patient satisfaction.

Wrapping It Up

PMMA 3D printed implants are a significant improvement in orthopedic surgery, providing a unique combination of aesthetics and strengths that benefit patients and surgeons alike.

With their remarkable biocompatibility, precise customization, and mechanical resilience, PMMA implants are set to play an increasingly important role in the treatment of a wide range of musculoskeletal diseases and accidents.

As 3D printing technology advances, the future holds promise for additional refinements and advancements in PMMA implant design and production, hence improving patient care and outcomes in orthopedic surgery.